From screw press machines to inspection equipment.

These are what our quality and productivity rely on.

Production Process

1. Cutting

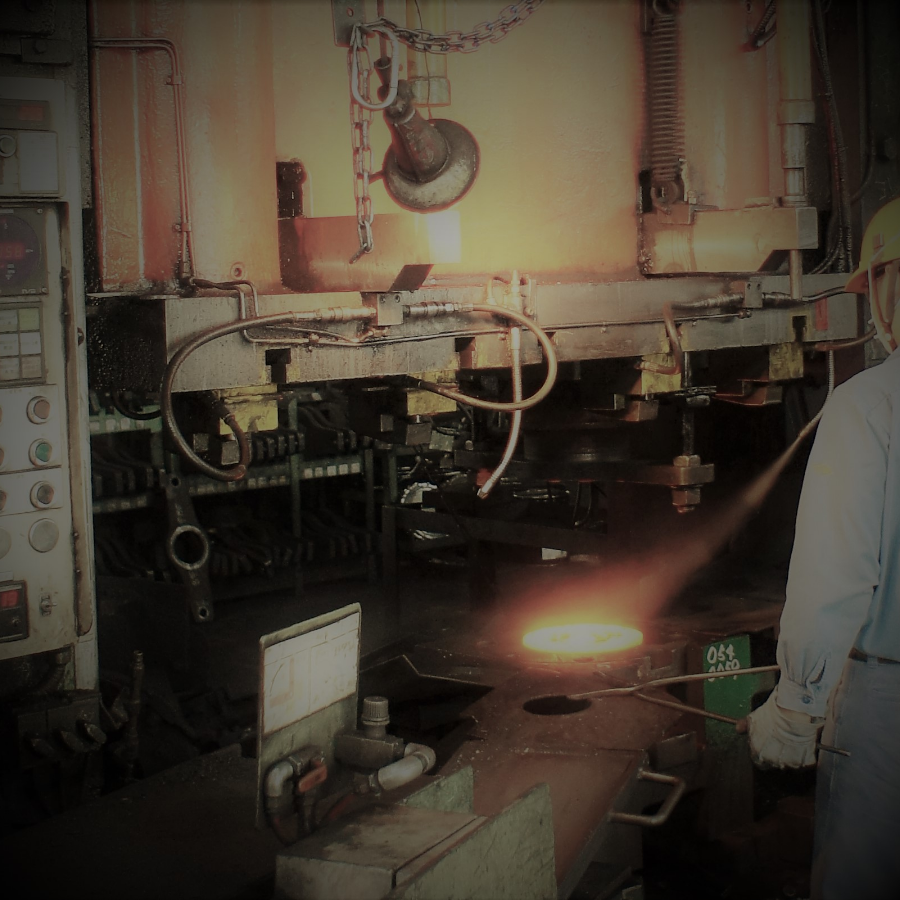

2. Heating

3. Forging

4. Testing

(There may be heat treating and machining between #3 and #4 depending on customer requirement.)

Forging

What is Forging?

It is a method of plastic deformation that is achieved by stroking and/or pressing metal material.

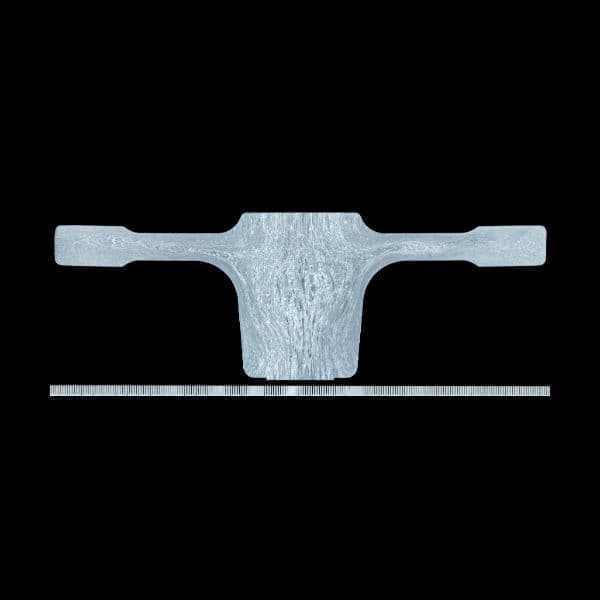

The stroking and/or pressing produces a dense and uniform metal grain flow to give superior mechanical properties such as high tensile strength and hardness.

The processing methods have been developed from the hand-made tools used by ancient blacksmiths into a variety of modern techniques such as our closed die screw press system.

Metal Grain Flow

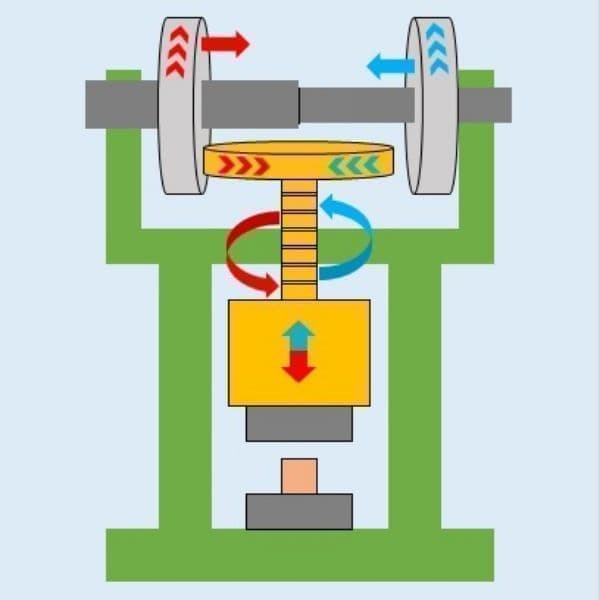

Advantage of Closed Die Screw Press Forging

The energy from high-speed spinning wheels is transferred to the screw and its rotary motion is converted into a vertical motion.

The stroke energy of the vertical motion is stronger than a hammer or crank type press so that 1 or 2 blow formation is possible.

In addition, the die forming creates products with less dimensional tolerance. This results in precise and complicated shapes such as hollow or extruded shapes with a draft angle of 0 to 1 degree attainable. This near NET shape reduces material waste and job labor by skipping or reducing the machining process.

In this way, our closed die screw press method balances productivity with dimensional preciseness.

Closed Die Screw Press

Facility & Equipment

Cutting Machine

| 1,000T Shear | Eumuco |

|---|---|

| 1,000T Shear | Manyo |

| Band Saw | Amada |

| Circular Saw | Tsune Seiki |

Press Machine

| 1,000T | Lasco (cold hydraulic press) |

|---|---|

| 1,600T | Hasenclever |

| 3,200T | Hasenclever |

| 4,000T | Siempelkamp |

| 4,000T | Hasenclever |

| 5,000T | Hasenclever |

| 6,300T | Hasenclever |

Cutting Machine

| 1,000T Shear | Eumuco |

|---|---|

| 1,000T Shear | Manyo |

| Band Saw | Amada |

| Circular Saw | Tsune Seiki |

Press Machine

| 1,000T | Lasco (cold hydraulic press) |

|---|---|

| 1,600T | Hasenclever |

| 3,200T | Hasenclever |

| 4,000T | Siempelkamp |

| 4,000T | Hasenclever |

| 5,000T | Hasenclever |

| 6,300T | Hasenclever |

| Electric Pit Type | TNK |

|---|---|

| Gas Continuous Type | Furnace Juko |

| Gas Batch Type | Nippon Selas |

| Tumbler Type | Sintokogyo |

|---|---|

| Table Type | Nicchu |

| Hunger Type | Nicchu |

| 110⍉ Automatic Single Spindle Welder | Sakae Industries |

|---|---|

| 60⍉ Automatic Double Spindle Welder | Sakae Industries |

| Spinning Trimmer | Mitsubishi Motor |

| Electric Pit Type | TNK |

|---|---|

| Gas Continuous Type | Furnace Juko |

| Gas Batch Type | Nippon Selas |

Blast Machine

| Tumbler Type | Sintokogyo |

|---|---|

| Table Type | Nicchu |

| Hunger Type | Nicchu |

| 110⍉ Automatic Single Spindle Welder | Sakae Industries |

|---|---|

| 60⍉ Automatic Double Spindle Welder | Sakae Industries |

| Spinning Trimmer | Mitsubishi Motor |

Machining

| Graphite Vertical Machining Center | Makino |

|---|---|

| Wire EDM | Makino |

| CNC Lathe | Okuma |

| NC Lathe | Okuma |

| General Purpose Lathe | Okuma |

Test & Inspection Equipment

| Magnetic Particle Testing | Nihon Denji Sokki |

|---|---|

| Electromechanical Universal Testing | Instron |

| Inverted Metaloscope | Olympus |

| 3D CMM | Mitutoyo |

| Contour Measuring | Mitutoyo |

| CNC Gear Tester | Tokyo Technical Instruments |

| Charpy Impact Test | Yonekura Manufacturing |

| Energy Dispersive X-ray Fluorescence Spectroscopy | Shimadzu |

| Emission Spectrophotometer | Spectro |

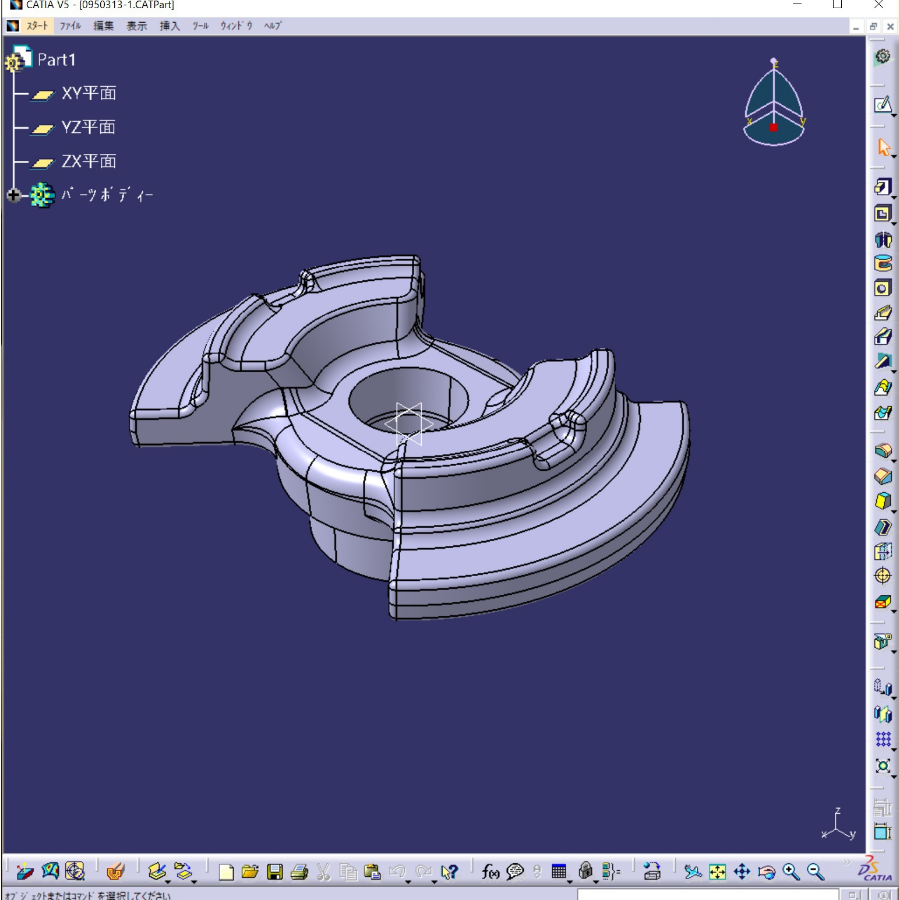

CAD

| CATIA V5 | Dassault Systemes |

|---|---|

| Pro/Engineer Wildfire 5 | PTC |

| iCAD | Fujitsu |